These engines operated at around 450 PSI of compression before ignition.This is higher than diesel engines, and caused many problems.The engines had to be built very heavily to withstand the pressures of compression and combustion.Even at that, the engines suffered broken frames and crankshafts. These engines required skilled operators to prevent such occurrences.Another problem was that the high compression would force the fuel past the rings, washing away the cylinder lubricating oil, resulting in short cylinder life.An existing Pohl oil engine needed to have the cylinder re-bored, new rings, and hairline cracks in the crankshaft professionally repaired by a specialty diesel crankshaft repair shop before it could be started.Existing examples of any Hvid oil engine require a skilled touch and lots of determination to start.

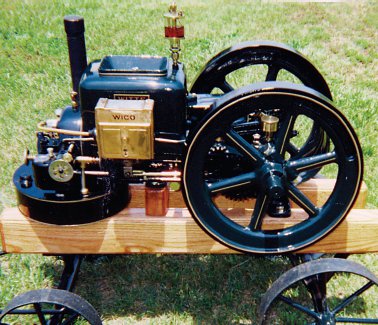

Pohl catalogs from 1914 period show small hopper cooled engine of 3 and 5 HP, semi portable and stationary styles, and a 15 HP stationary tank cooled engine.These engines were Hvid oil engines, although the catalog describes these as semi Diesel engines.The frames of the 3 HP engines were enclosed. The 5 HP engines were of a more conventional design, and are shown in the catalog.Another catalog lists the smaller engines as 2 ½ HP.These engines were advertised as late as 1917, in the Oneida County Farm Directory.

Pohl Oil Engine, 5 HP as advertised in the Oneida County Farm Directory

As noted before, there also appears to be a connection between Geo. D. Pohl Mfg. Co, and Jones oil engines of Syracuse.The Jones catalogs illustrate a 5 HP engine identical to the Pohl offering, and existing engines of the 3 HP style have some similarities, but are not identical.Jones, for example, chose to cast its name into the hopper, and Pohl used powered intake and exhaust valves, while the Jones engines have an atmospheric valve.

The Hvid engines enjoyed a brief popularity among engine manufacturers, until the problems from field use became apparent.This turned out to be a dead end in the evolution of the internal combustion engines.

15 HP Pohl Hvid engine, which used the 20 HP gasoline engine frame

Compare this catalog picture to the Oil engine above.

The End

After many years of prosperity, a number of problems began to beset the company.In the latter years, Pohl had trouble getting paid.Frequently, his customers (especially the cotton people in Texas) couldn’t pay their notes, so Pohl couldn’t pay his suppliers. The company would take engines in trade, which were refurbished and re-sold, a marginal business at best.

In the late teens, competition from International Harvester and Fairbanks, Morse & Co. was intense.The IHC “M” and F-M “Z” were cheap, good, and mass produced in quantities never heard of before.Pohl’s design at this time was decidedly dated and expensive, with its elegant sideshaft and signature governor.Their gamble with the Hvid oil engines was doomed to failure.The tractor also failed to materialize. Electric motors were becoming popular in industrial applications, and farmers bought the cheap, mass produces engines or the new cheap tractors.Around 1918 the Bank of Vernon padlocked the factory door, and production ceased. The patterns for the once mighty Pohl engines were burned for firewood by the family. The factory was abandoned and finally torn down.The office building was used as a print shop for a time, but this, too, was eventually abandoned.Somewhat less than 3000 engines were ever numbered in the Pohl shops. Uebler Milking Machine Co, of Vernon probably took over the manufacture of the milk processing equipment.

Other than the coveted engines in the hands of collectors, or, perhaps, still on location in barns or hedgerows, few remains of the Geo. D. Pohl Mfg. Co. still exist. Catalogs, postcards, rulers and other advertising material exist, but these are rare.Correspondence from the company also exists, but this is even rarer.It is estimated that only about 60 Advance engines exist in the world today.

George Daniel Pohl died January 5, 1926.He had just turned 70.He is buried in the family plot in the Cooper St. Cemetery in Vernon.

Chapter 4 Design of the Gas and Gasoline Engines

Witte Gas Engine Serial Numbers

The Geo. D. Pohl Manufacturing Co. built Advance internal combustion engines starting around 1894 in Ava, NY.Production was continued in Vernon from 1898 to about 1918.It is estimated that less than 50 gas or gasoline engines were made in Ava, although steam engines may have been more numerous.None of the Ava made internal combustion engines are known to exist.

Advance gas and gasoline engines are sideshaft engines of the throttling governor type.Most of them had a very distinctive governor virtually identical to the Hamilton engines, driven from the sideshaft.Later, a different style “upside down” governor was used on some of the larger engines.

Since Pohl’s primary market for these engines were the farms in upstate New York, where gaseous fuels were not readily available, they were offered as gasoline engines from the beginning.Gas engines, which burned either illuminating gas from town supplies, natural gas, or producer gas made on-site from coal or wood, were manufactured for industrial users.Kerosene experiments began in 1913, culminating in the Hvid compression ignition engine design.These were also intended primarily for farm use.

Pohl engine with a gas mixer.

The smaller horsepower engines had atmospheric intake valves. As the piston moved out during the intake stroke, a vacuum was created in the cylinder, drawing the intake valve open, and allowing the gas-air mixture into the cylinder.Larger engines had powered intake valves.The configuration of these valves varied on the larger engines.

The 6 and 8 HP engines used counterweights cast into the flywheels to balance the engine, and the larger engines used weights on the crank itself.Some of the earlier large horsepower engines used a disk type crank weight. Machined, forged connecting rods were used through production, as well as machined drop forged crankshafts.

Early Advance engine, around 1900.Note the disk crank and the plunger type cooling pump behind the rear wheel.

At first, the engines were only offered as tank cooled versions, either with a thermosyphon cooling system, or a water pump through a screen cooling system.Later, hopper cooled engines of 6, 8, and 10 HP were offered.The tank cooled engines could also be cooled with a source of continuously flowing water, such as a village water supply.

Ignition usually consisted of make and break type of ignition.This involved a set of electrical points situated inside the cylinder on a removable plug, called an igniter.One of the points was insulated from the frame, and the other was allowed to pivot in the casting.During the compression stroke, near the point of ignition, a trip on the end of the sideshaft closed the movable point to the insulated point.At the exact time of ignition, the trip slipped off a pin on the sideshaft, allowing the points to rapidly separate.The points were energized with electricity, and when they separated, a spark was created between the points, thus igniting the charge in the cylinder.A large coil of wire around a soft iron core was used to “push” the spark across the gap for a hotter spark.Power was supplied from a battery or magneto.Batteries used included the venerable Edison type RR wet cell, and Acme Rapid Fire dry cells.

Pohl igniter

Since the engine was a throttling governor type, it fired every second revolution, as opposed to the hit and miss type of operation, which allowed the engine to fire only when its speed fell below the point determined by the governor.As a result, most Pohl engines used some sort of magneto for supplying the current for ignition, as batteries would quickly be run down.Early engines were supplied with magnetos made by the Hendricks Novelty Works, with either a friction drive, that rubbed on the flywheel rim, or belt driven, from a pulley on the crankshaft. These setups required a battery to start the engine. Later, Accurate and Webster oscillating magnetos were supplied as units integrated into the igniter.This eliminated the need for storage batteries.Also available on later engines was a gear driven magneto placed on a platform between the flywheel and frame, and geared to the sideshaft.This was timed to give the greatest spark at the time the igniter tripped.The belt driven magnetos were also offered on later engines. Hot tube ignition, where a constantly heated tube was used for igniting the charge, and spark plug ignition were available at various times as options.Pohl was also interested in “igniters” from the Witherbee Igniter Company, maker of the famous WICO magnetos, although these were not adopted.

The throttling governor system consists of a round butterfly valve in the path of the fuel and air mix.As the engine speeds up, the governor closes the valve through a series of links, including a geared sector that meshes with a partial gear attached to the butterfly valve.The engines had a design flaw that, to this day, is still suffered upon these otherwise fine engines.Normally, when the valve closes, it contacts the sides of the intake passage, keeping it from going further than fully closed.As the engine heats up, the iron passage expands, and the butterfly valve can go past closed, allowing the engine to run away.This has happened to engines in the distant past, as well as the ones that have survived to this day.The solution is to keep the butterfly valve from going past vertical in a positive manner. This is done by either limiting the geared sector movement (6 HP), or a pin to keep the butterfly valve from moving past the closed position.

Pohl Governor

All larger Advance engines, and many of the smaller ones, were equipped with a clutch pulley.These was made by Glen W. Munson Co., of Utica, NY, and allowed the engine to be disconnected from its load when starting or for any other reason.

Several carts were used on the portable engines.Pohl made their own carts, which are characterized by a diagonal cut to the main frames under the driver’s footboard.These were not cut with a saw.A series of closely spaced holes were drilled along the desired line to separate the metal and create the diagonal cut.Other carts used on Pohl engines include Bittendorf carts, and wooden wheeled carts.The wooden carts were referred to as “cheap” carts in Pohl correspondence.Portable engines used a short sub base instead of the full base, and the fuel pump position was moved to a point just under the governor.

Catalogs from the early 1900’s illustrate tank cooled engines only, starting with a 3 to 7 HP gas or gasoline engine.These were similar in construction, but the gas version, meant to run on natural or producer gas, had a gas mixer in place of the mixer and fuel delivery system of the gasoline engine.

Engines of a slightly different design was developed for the 10 to 50 HP range.These gas or gasoline engines featured a very long stroke, with a correspondingly long base, giving the engine a very distinctive appearance.Larger horsepower engines were developed from these by simply coupling 2 single cylinder frames together at the crankshaft with an extra large belt pulley.

Early 2 cylinder Advance engine.

Other options available in the early 1900’s include semi portable engines, with thermosyphon cooling, and portable engines with a plunger water pump operated from the sideshaft.Complete producer gas outfits, which manufactured the gas needed for the engine from coal in a unit called a “producer”, were available on special order.These were purchased from companies like Syracuse Industrial Gas Co. of Syracuse and Vernon, NY, and Wisconsin Engine Co. of Corliss, WI.Pohl was also prepared to supply electrical generators and complete electric lighting outfits with their engines.

A later catalog, from about 1916, shows a rather different lineup.Now, the range began at 6 HP, with Standard Stationary engines available in 6, 8, 10, and 12 HP models. Standard Hopper Cooled Stationary engines were available in the same range, as well as 16 and 20 HP, and 25, 30, and 40 HP Standard Stationary tank cooled engines.The 16 and 20 HP engines noted above now had a different “upside down” governor than the other engines in the line, which used the same classic Pohl governor.Tank cooled engines were offered in 6, 8, 10, and 12 HP sizes, with or without the cart.These were also offered in the 16, 20, 25, 30, and 40 HP sizes noted above, and were now supplied with a belt driven centrifugal water pump.

Advance 16 to 40 HP.Note the Pohl cart and upside down governor.

Farmers Favorite hopper cooled engines of 6, 8, and 10 HP engines were available as semi portable or portable versions.These were a lower cost competition engine, with unfinished forged connecting rods, unfinished cranks, and lightweight frames.Catalog illustrations show these engines with crank guards with an oiler on the guard for the crankshaft, but no surviving smaller engines are known to have these guards.These were probably omitted on the Farmers Favorite engines as a cost cutting measure.These engines had ‘Farmers Favorite” cast into the hopper, but the tag usually reads “Advance” engines, or “Advance Type ‘S’”.An “Advance” decal was applied to the front of the hopper.Powell oilers were used on all engines throughout production.

Farmers Favorite Semi Portable engine.

The catalog also describes 2 ½ and 5 HP oil engines of the Hvid style discussed elsewhere. Heavy duty engines, of 35, 50, 60, and 75 HP were offered.It is noted that the engines from 40 to 75 HP were single cylinder single acting engines with a single flywheel, and either a center crank or a side crank arrangement.From 70 to 300 HP, the engines were twin cylinder, tandem, or twin tandem with double acting cylinders.The conflicts and overlap in the horsepower in the above lineups, and the general nature of the engines indicate that these were not built by Pohl at all, but were bought in on an as-needed basis.Manufacturers of these include Struthers-Wells Co. of Warren, PA, and Riverside Engine Co. of Oil City, PA.

Twin tandem engine offered by Pohl, made by Riverside Engine Co.

In latter days, Pohl stopped manufacturing the 3 and 4 HP engines of earlier years, since by 1912 the smaller engines were being mass-produced cheaply by other companies.To cover this range, they bought engines from some of these companies.A 4 HP vertical engine made by Peerless Engine Company of Lansing MI was offered for a time beginning around 1909.In 1912 they offered a variety of small engines, including 1 ½ HP and 2 ½ HP Holbrook and Armstrong, Gray Motor Company of Detroit, Sta-Rite, of Racine WI, and J. Thompson & Sons Mfg. Co., of Beloit, WI.The latter engines were tagged with Advance tags before they were shipped from the factory, and were purchased in very small quantities.Pohl was also the eastern distributor for Brownwall air and hopper cooled engines from 1 ½ to 3 ½ HP.Pohl solicited other companies for smaller engines, including Turner Manufacturing Company of Port Washington, WI, makers of Simplicity engines.These engines were not ordered, since it required buying a train carload of engines at once.Pohl shopped around for the cheapest small engines he could find.Most of the above engines were offered during the same time period.About 1913, they carried the engines of Nelson Brothers, of Saginaw, MI, in 1 ½ to 2 ½ HP sizes.They apparently settled on this design in the end.Existing engines carry the standard “Advance” tag.

All of the engines, be they made or purchased, were numbered consecutively.Engines were often sold before they were made. Engines were also taken in on trade including names such as Webster, Woodpecker, and old Advance engines.These were reconditioned and re-sold to anyone who wanted a used engine.

Pohl 2 ½ HP engine, made by Nelson Brothers

The following is a summary of known bore and stroke information for the various engine types manufactured by Pohl:

Bore & StrokeHPYear

6 X 1151901

5 X 951906

5 ½ X 951909

6 X 1161906

5 ½ X 961913

6 X 1181913

6 X 981913*

7 X 1281905-1907

7 X 12101912

8 ½ X 14101902

8 ½ X 14151909-1910

Krisis ini disebabkan oleh Toneri Ōtsutsuki, keturunan terakhir dari hidup saudara kembar Hagoromo di Hamura yang keluarganya tinggal di bulan sejak pembentukannya. Download film naruto

shippuden episode 91 subtitle indonesia.

8 ½ X 14161913

9 ½ X 14131904

9 ½ X 14 201910

10 1/2 X 1625

11 ½ X 18301913

11 ½ X 20251913

16 ½ X 2080

*This was probably a speed change

This chart shows how the engines were re-rated as the years went on and the designs changed.The engines were usually overrated to begin with, but with a slight increase in RPM, more horsepower could be got from the same engine.This was common practice for engine manufacturers of the time.

Examination of a few existing engines reveals many design differences.For example, a 10 HP Portable engine, serial number 818, has flywheels normally used on the 8 HP engine.The flywheel design for the 6 HP engine also underwent a change between engines 1455 and 1657.This may be due to the latter engine being a competitive type S engine. The earlier one, with heavier flywheels, is a standard offering.Since production of these engines was never more than a couple of hundred copies a year, they were probably hand built and fitted for the most part.Although parts may be interchangeable, each engine had a character of its own, still seen to this day.

Engine 1657

Engine 1657, a 6 HP “Farmer’s Favorite” Type S semi-portable engine was built early in 1914, and spent its working life on a farm near Steuben, NY.It was sold at auction in the 1960’s for the princely sum of $20.00.It then went to Charlie Pierce, engine collector, of Deansboro, NY.Charlie passed away, and the engine was found its way to Gary Love, of Canandaigua, around 1990.In 2003, Gary traded the engine to a collector in Indiana.It made the trip out to Indiana, only to come right back a week later to Lockport, NY, through another trade with Wayne Grenning.It was immediately traded to Woody Sins, and brought back to New Hartford, New York, about 15 miles from where it was built, and 20 miles from where it spent its working life.Incidentally, this engine suffered a runaway during an engine show in 2006.The problem was quickly rectified.It also had the distinction of going back to its place of origin, when it was featured at the annual Customer Appreciation Day at Pohl’s Feedway in Vernon, September 21, 2006.The Feedway is situated across the parking lot from the site of the original Pohl factory.

Family Tragedy

As mentioned previously, George Pohl’s brother, Henry joined George after the move from Ava. He was working on a larger engine in the course of his employment at the factory, and was reaching between the spokes of the flywheel, when the engine fired, severely injuring him. He died as a result of his injuries.His son, Emerson, was in school at the time, and had to leave in order to support his family.He was employed at the Pohl factory as a machinist until it closed. This tragedy is a lesson for all who still work on these old marvels: always disable the ignition before reaching between the spokes of an engine.This is especially true with large hot tube fired engines.

Another tragedy is described in a letter to the company of an incident where “The man caught his jumper in the governor on my Advance engine and stripped the gears, both on the governor and the cam shaft”.This engine was a 4 HP engine, number 942, and was used for separating milk and pumping water.It is not recorded what happened to “the man”.

Echoes of the past

Bill Graves, of Florence, NY describes an engine he tried to buy from a man in Remsen.The man wouldn’t sell.Apparently, the engine ran away on him and startled him so that he wanted to leave it behind the barn and “let it rot!”Eventually, the man passed away and it was purchased by another collector.This is the 10 HP stationary engine that was at the Flywheels and pulleys show all those years ago.

David Sins, my father, used to tell a story of a machine shop in the North Country operated by a man named Plumber in Constableville, NY that ran with a Pohl engine.He said that they used a rain barrel full of water for a muffler.This would only be possible with a throttling engine like the Advance.

Mahlon York, of Clinton NY relates a tale from his childhood concerning a 3 HP Pohl oil engine.It was rescued when he was a teenager and the family had it bored out with new rings, and used it for a time.Eventually, it was traded for some iron that was needed, and tragically scrapped.This engine was reportedly easy to start by just flipping the engine back against compression, and cranking it through once or twice to start it.This is an amazing tale, indeed!

I had the distinct pleasure of talking to Robert Morris, a lifelong Vernon resident.At the time of the conversation, he was 98 years old.He told of the days when he used to draw milk to a milk plant next to the tracks in Vernon, behind the rail station, and across from the Pohl factory.He remembers seeing the engines outside the factory, lined up against the wall, and being test run prior to shipment.

The deed to the Sins family farm records a land transaction between George Pohl, and Achilles Henry Sins, the great, great grandfather of the author.In this case, George Pohl is the uncle of George D. Pohl.The parcel of land in question has yet to be located.